The New Revolution in Printing in Ilford: DTF – Direct to Film Printing

The New Revolution in Printing in Ilford: DTF – Direct to Film Printing

The Direct to Garment (DTG) printing had been ruling the printing industry in Redbridge, Ilford for more than 2 decades along with its bottlenecks and challenges. Some of the drawbacks of DTG include the slow process and its high cost for large orders. It can also have issues with ink clogging and maintenance, and it can fade or crack over time.

Also read: Screen Printing vs DTG (direct to Garment) Printing

The print market in Ilford is revolutionized by DTF printing technique allowing you to create stunning designs with excellent colour accuracy on various fabrics and materials. Whether you are a hobbyist or a professional, DTF printing can open up new possibilities for your creativity and business.

What is DTF – Direct to Film Printing

DTF stands for direct-to-film, and it involves printing the design on a thin film that is then transferred to the fabric using heat and pressure. This technique allows you to create high-quality prints on various fabrics and materials.

How Does DTF Printing Work?

Here are the main steps of the DTF printing process:

1. Prepare your design: You can use any graphic software to create your design, such as Photoshop, Illustrator, or CorelDraw. Make sure to adjust the size, resolution, and colour mode of your design according to your printer and film settings.

2. Print your design on the DTF film: Load the film into your printer and select the appropriate settings for your ink type and quality. You can print on either side of the film, but make sure to mirror your design if you print on the glossy side.

3. Apply the hot melt powder: After printing, you need to coat your design with a thin layer of hot melt powder, which is a special adhesive that will bond your design to the fabric. You can use a manual or automatic powder shaker to apply the powder evenly over the film.

4. Cure the film: The film is heated to activate the hot melt powder and make it sticky with the help of a heat press or a tunnel dryer to cure the film for about 90 seconds at 160°C (320°F).

5. Peel off the film: Once the film is cured, the backing paper is peeled off from the film, leaving only your design on the transparent film.

6. Transfer your design to the fabric: Finally, the design can be transferred to any fabric or material you want, such as cotton, polyester, leather, wood, metal, etc. Aheat press or an iron to can be used apply heat and pressure to the film and fabric for about 15 seconds at 160°C (320°F). Peel off the film while it is still hot, and your print is done!

Advantages of DTF Printing

- Some of the advantages of DTG are that it can produce high-quality prints with vivid colours and details, it can print on any colour of fabric.

- It has low setup costs and minimum order quantities.

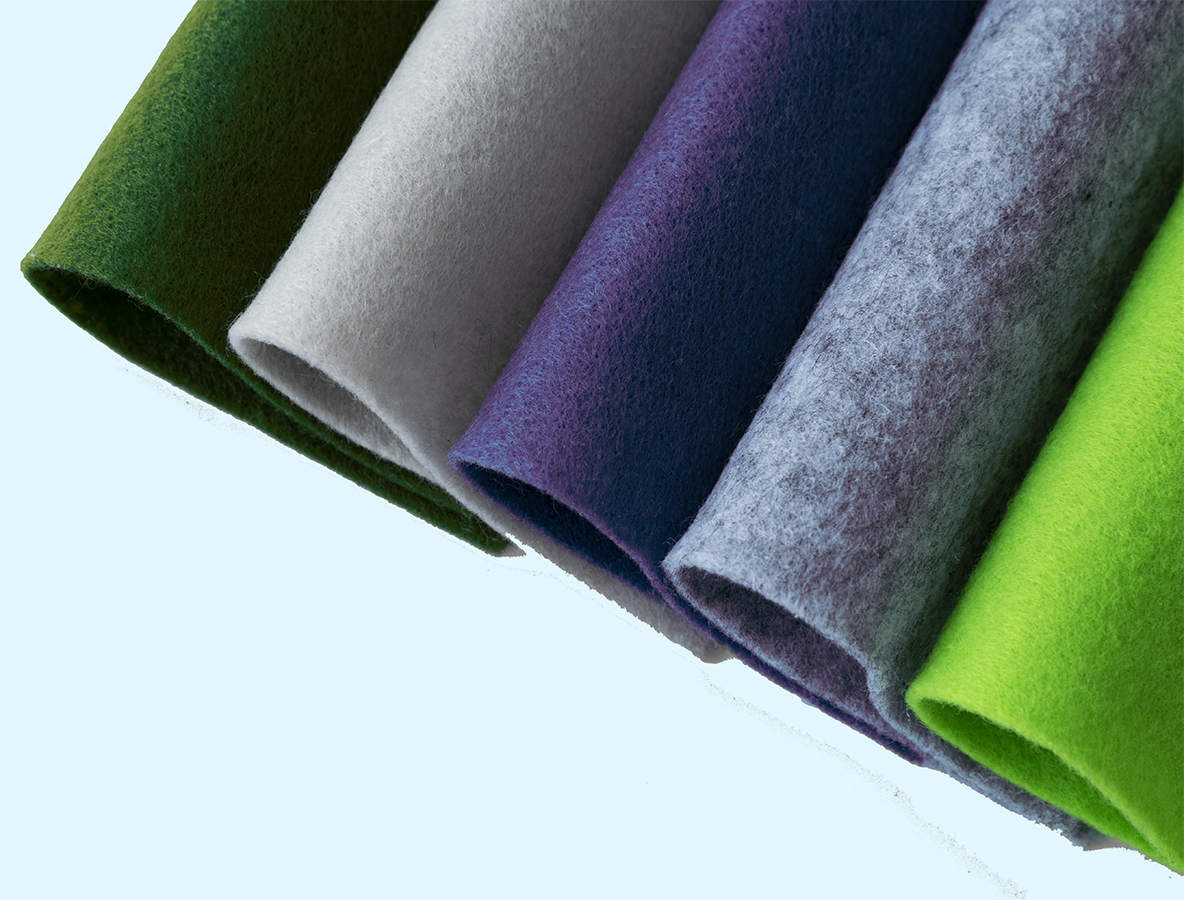

- It can print on a variety of fabrics and materials, such as cotton, polyester, leather, and metal.

- It can produce durable prints that resist fading and cracking.

- It can be faster and cheaper for large orders.

After knowing the basics of DTF and DTG printing, their pros and cons, here are some tips on when to choose what:

DTF VS DTG Printing – A Comparison

Both DTF and DTG printing have spectacular features and give amazing results but to have an in-depth knowledge of what suits your design best is essential. Here are some tips for you:

- Suitable Fabrics: The direct-to-film printing method is applicable to polyester, cotton, fleece, nylon, and such fabric blends giving you a variety of options for your printing business. However, Direct-to-garment printing is best suited for natural fabrics like cotton, bamboo, linen, or such fabric blends. That’s because the ink used in DTG printing binds with the natural fabric fibers better than synthetic fabrics.

- Vibrancy of Colours: DTF printing can print on any color including dark, light, and blends as it uses CMYK colours (cyan, magenta, yellow, and black) and white ink for the base. Every design will be vibrant and vivid, no matter the fabric colour or type. DTG printing gives vibrant colours with white base but only for black and colourful fabrics. It is advised, however to design in RGB (red, green, blue) mode and shifts in colours must be expected in results.

- Print Quality: DTF printing can produce vibrant and opaque prints that stand out on any background. DTF printing supports photos, detailed, full-color designs, fine art, small text, graphics, and more. The prints are sharp, clear, and realistic, so they’ll be close to the original design. Whereas DTG printing produces more realistic and subtle prints that blend in with the fabric. The prints are clear and detailed but the clarity of the design may be affected as the ink soaks in the fabric.

- The Process: DTF printing requires more steps and materials, such as film, powder, and heat press while DTG printing requires less steps and materials, as you only need a printer and ink.

- The Initial Investment: DTF printing has a lower initial cost, as the equipment and consumables are cheaper than DTG printing. DTG printing has a higher initial cost, as the printer and ink are more expensive than DTF printing.

- Production Speed: DTF printing has a higher production speed, as you can print multiple designs on one film and press them onto different garments. DTG printing has a lower production speed, as you have to print each design individually on each garment.

So, when should you choose DTF or DTG printing? Here are some factors to consider:

- If you want to print on dark or synthetic fabrics, DTF printing may be a better option than DTG printing.

- If you want to print detailed or gradient designs, DTG printing may be a better option than DTF printing.

- If you want to print large or frequent orders, DTF printing may be a better option.

- If you want to print high-quality and long-lasting prints, both DTF and DTG printing can deliver good results.

For customized printing services in Redbridge, Ilford, London, for screen, digital transfer, vinyl and embroidery, visit our store https://custommadetshirts.co.uk/

We deliver all over UK and EU!