Screen Printing vs DTG (direct to Garment) Printing

Screen Printing vs DTG (direct to Garment) Printing

Whether you’re an aspiring artist, a design enthusiast, or simply curious about the magic behind the printed world, knowledge of different t shirt printing techniques is crucial. There are several different printing methods that can be used to create t-shirt designs, each with its own advantages and limitations. Here are some of the most common printing methods:

Screen Printing

Screen printing is a traditional printing method that involves creating a stencil or “screen” for each color in the design, then using a squeegee to force ink through the screen and onto the shirt. It is especially well-suited for designs with fewer colors or larger areas of solid color.

Working

A separate screen needs to be created for each color in the design. This is done by applying a light-sensitive emulsion to the screen, then exposing it to light with the artwork on top. The emulsion hardens where the light hits it, creating a stencil on the screen.

Finally, the shirt is placed on a flat surface, and the screen is positioned over the shirt. The ink is then pushed through the screen using a squeegee, which forces the ink onto the shirt. The screen is lifted away, and the shirt is moved onto a drying rack or conveyor belt.

After printing, the ink needs to be cured to ensure that it sets properly and doesn’t wash out. This is typically done by heating the shirt to a high temperature for a certain amount of time, which causes the ink to bond with the fabric.

Screen printing has several advantages and limitations when it comes to creating t-shirt designs. Here are some of the main advantages and limitations of screen printing:

Advantages of Screen Printing

Vibrant Colors: Screen printing can produce bright, vivid colors that are long-lasting and resistant to fading.

Durability: Screen printing creates a thick layer of ink that is more durable and long-lasting than other printing methods.

Versatility: Screen printing can be used on a wide variety of fabrics, including cotton, polyester, and blends.

Cost-effective: Screen printing is cost-effective for large quantities of shirts, as the cost per shirt decreases as the quantity increases.

Great for simple designs: Screen printing is ideal for designs with fewer colors or large areas of solid color.

Limitations of Screen printing

Not suitable for complex designs: Screen printing can be challenging for designs with many colors, fine details, or gradients.

Set-up time: Screen printing involves a set-up process to create the screens and mix the inks, which can be time-consuming.

Minimum order quantity: Some screen-printing companies may have minimum order quantities, which may not be cost-effective for small orders.

Ink transparency: Screen printing inks can be opaque, which means that the color of the shirt can affect the final color of the design.

Not eco-friendly: Screen printing can produce a lot of waste, as screens and inks need to be disposed of properly to avoid environmental damage.

Overall, screen printing is a popular and durable printing method that is well-suited for simple designs and large quantities of shirts. However, it may not be the best choice for more complex designs or small orders.

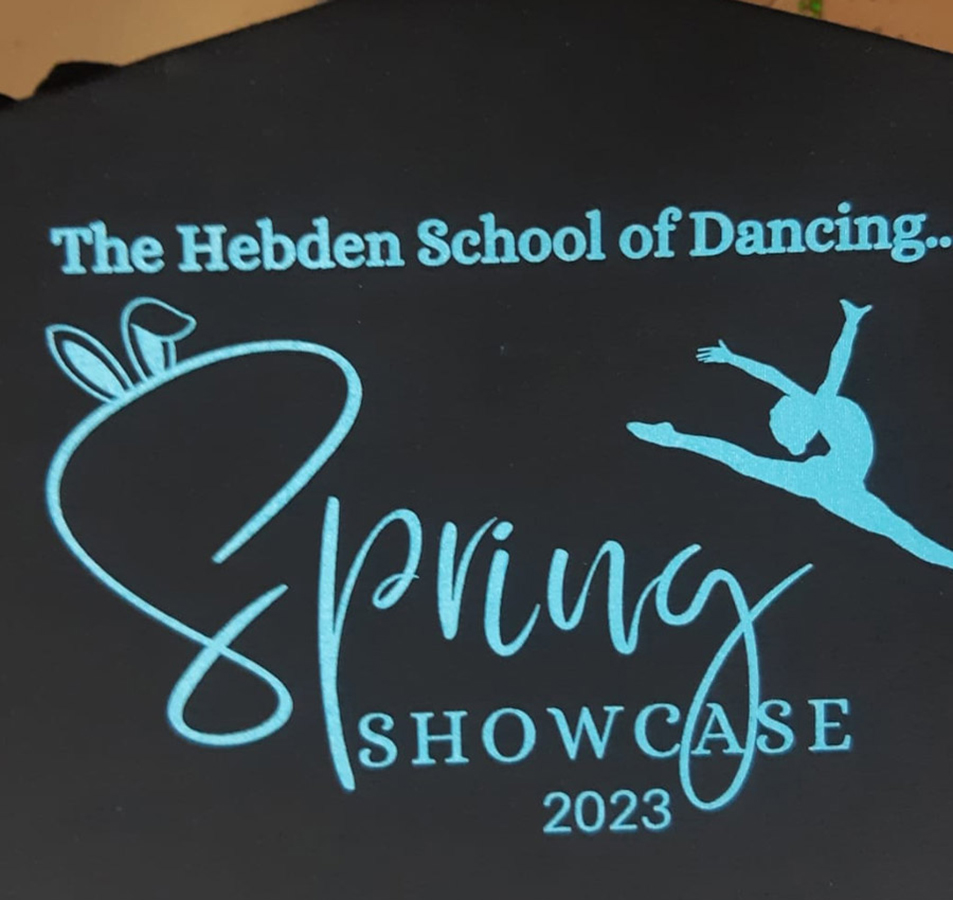

Direct to Garment Printing

DTG printing uses a specialized printer that can print full-color designs directly onto the shirt, similar to how an inkjet printer works. This method is best for detailed designs with many colors or gradients.

First and foremost, the artwork needs to be in a high-resolution format, and the colors should be separated into their own layers.

After printing, the shirt needs to be dried and cured to ensure that the ink sets properly and doesn’t wash out. This is typically done using a heat press or a conveyor dryer.

The artwork is loaded into the DTG printer, and the shirt is placed onto the printer’s platen. The printer sprays the ink onto the shirt, creating the design.

DTG printing is a relatively new printing method that has become increasingly popular due to its ability to produce highly detailed designs with a wide range of colors.

Advantages of Direct to Garment Printing

Soft feel: Because the ink is absorbed into the fibers of the shirt, DTG printing results in a soft feel that is often preferred over the thicker ink layer created by screen printing.

No set-up costs: Unlike screen printing, which requires the creation of screens and the mixing of inks, DTG printing does not require any set-up costs.

Good for small orders: DTG printing is ideal for small orders, as there are no minimum order quantities.

High Quality: DTG printing can produce highly detailed designs with a wide range of colors and gradients, resulting in a high-quality finished product.

Limitations of Direct to Garment Printing

DTG printing works best on 100% cotton fabrics or blends with high cotton content and may not work as well on other materials such as polyester.

Cost: DTG printing can be more expensive than other printing methods, especially for large quantities of shirts.

Not ideal for dark shirts: DTG printing works best on light-colored shirts, as the ink is not as opaque as screen printing inks and can be affected by the color of the shirt.

Not as durable: DTG prints may not be as durable as screen prints, as the ink is absorbed into the fibers of the shirt rather than sitting on top of the fabric.

Limited on certain fabrics: DTG printing works best on 100% cotton fabrics or blends with high cotton content and may not work as well on other materials such as polyester.

If you’re wondering which printing technique to choose, here are some tips for you:

Consider the design: If your design has a lot of colors, gradients, or fine details, DTG printing may be the best choice. However, if your design is simpler with fewer colors, screen printing may be a more cost-effective option.

Think about the quantity: If you only need a small number of shirts, DTG printing may be the best choice as it doesn’t have any minimum order quantities. However, if you need a large quantity of shirts, screen printing may be more cost-effective as the cost per shirt decreases as the quantity increases.

Check the fabric: If you’re printing on a fabric that is not 100% cotton, DTG printing may not work as well. Screen printing may be a better option for materials such as polyester or blends.

Consider your budget: DTG printing can be more expensive than screen printing, especially for large quantities of shirts. If you’re working with a tight budget, screen printing may be a better choice.

Think about the desired outcome: If you want a softer feel and a more vintage look, DTG printing may be the better choice. If you want a bolder, more opaque print, screen printing may be the better choice.

Happy printing!!!

Visit http://www.custommadetshirts.co.uk/ for all your printing solutions with best printers in town covering all areas of Redbridge including Woodford Wells, Hainault Estate, Woodford, Woodford Bridge, Barkingside, Snaresbrook, Wanstead, Newbury Park, Chadwell Heath, Seven Kings, Leytonstone, Aldersbrook, Cranbrook Park, Goodmayes, and Ilford.