7 Common Problems in Sublimation Printing and Dyeing and How to Fix Them

7 Common Problems in Sublimation Printing and Dyeing and How to Fix Them

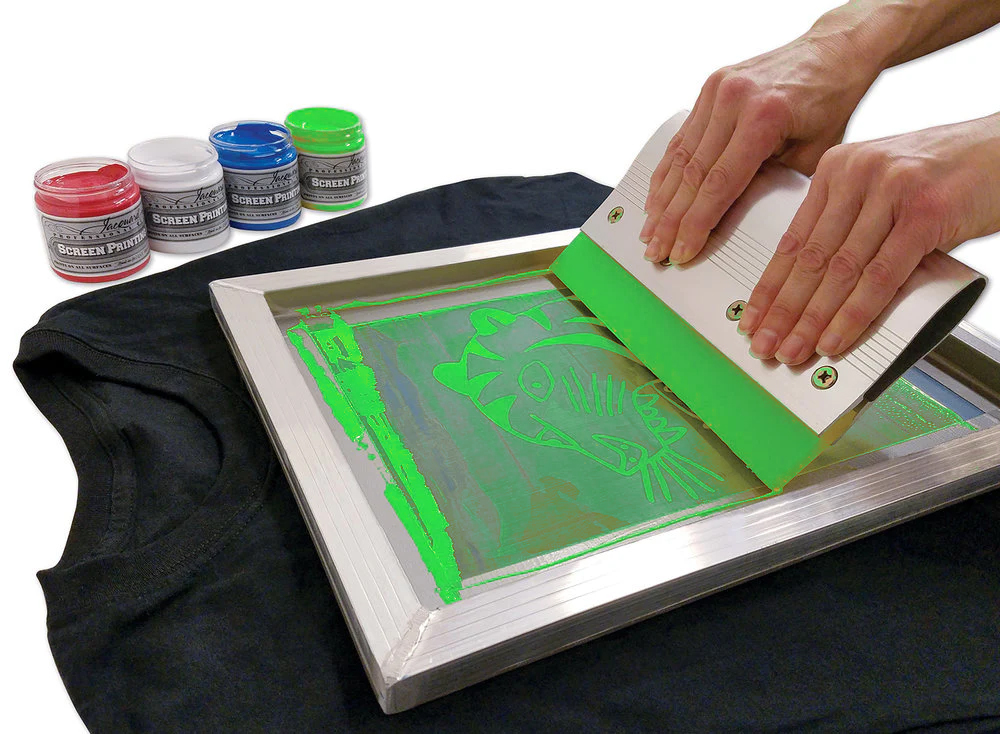

For t-shirt printing businesses in London, particularly in Redbridge, Ilford, where demand for customised apparel is high, one might look for more and more innovative, fast and reliable techniques of customized printing. Sublimation Dyeing is an effective and efficient resort to all of your requirements. However, as with any innovative process, there are bound to be challenges along the way. From colour inconsistencies to heat press mishaps the trouble can be real.

With the right knowledge and approach one can avoid such problems and hurdles to ensure a smooth printing process. We have compiled a list of some common issues with Sublimation Dyeing and their possible solutions in this guide.

Image Ghosting

Image ghosting can be a significant problem that affects both the quality of the product and customer satisfaction. It is one of the most common and frustrating issues faced by printers is image ghosting. This phenomenon occurs when a faint duplicate of the intended image appears on the final printed product, resulting in a blurry or distorted appearance.

In simpler words it is just like a second faint version or a shadow by the side of your image transferred. It simply occurs when the sublimation transfer paper moves even slightly during the sublimation process. This can happen at the time when you open or close your heat press, or the paper is not firmly placed against the substrate.

The Solution:

It is recommended to tape down your hard material substrates to the sublimation paper with a thermal tape. For printing on fabrics, adhesive sprays can also be used to keep the paper intact and also make sure that you remove the transfer paper immediately after pressing. The paper may also shift if not taped well, if you are using an auto-open press.

You may also get broad format printing transfer papers to ensure flawless transfers as they have high quality adhesives.

Transfers coming out not Vibrant

Some very common and standard issues faced by many new sublimation printing experts are getting unclear, non-vibrant or less vibrant colours in the transfers.

The Solution:

First, ensure that you’re using the right sublimation paper for your printing system. It’s typically bright white and smooth on one side and generally off white on the other side. Also make sure that you are printing on the correct side i.e. the bright-white side.

Also, if you’re printing with a Sawgrass Virtuoso SG400 or SG800, the bright white side will load face-down in the tray.

Make sure you use the correct colour correction program to avoid this issue.

Previously transferred image visible on a new blank transfer

The sublimation ink has the tendency to bleed onto the bottom and top platen of your press during heat transfer and it may get transferred to your next blank transfer.

The Solution:

You can fix this by preventing the sublimation ink from getting onto your top and bottom platen with the help of Teflon wrap or Teflon sheets for each platen. You only have to wipe away the excess ink after each press after every use and are absolutely reusable.

Another alternative is to use silicone-treated sheets, but they need to be discarded after use.

Banding

This is when dark stripes or bands appear across the print, usually due to excess moisture or heat on some areas of the design. Banding looks like lines of missing ink on the printout.

The Solution:

To fix this, you can wash the garment before printing, dry it well, and use a heat press with an adjustable temperature setting.

You may also have a clog somewhere in your nozzles of your sublimation printer. Do a printhead cleaning as a last resort.

Blurry and Faded Transfer

Image blurring may occur because your substrate received too much time/temperature in the heat press, and it starts to bleed out because of this excess.

The Solution:

Double-checking the recommended settings from the company where you purchased your sublimation blanks is going to help and also double-check the temperature of the top platen on your press. Reducing the transfer time and attempt to print again.

Small dots in transfer

Your design may also become blurry or smudgy with small dots on the output usually due to water getting between the ink and the fabric.

The Solution:

To avoid moisture, you can use a dehumidifier in your printing area, store your paper in a dry place, and press your garment for longer to remove any moisture.

Ink not accepted by the substrate

Sublimation printing is not meant for every fabric. When the transfer is less vibrant and stretchy, and the substrate is not accepting the ink, check the blend of your fabric.

The Solution:

Your product blank needs to be made of polyester or have a polyester coating. For fabrics, 100 percent white polyester is recommended for the best transfer or should be a poly blend at least which will yield less vibrant and vintage look.

A 100 percent cotton will not sublime, and your transfer will wash away in the first wash cycle.

For you ultimate customized printing solutions in Redbridge, Ilford for t shirts, mugs, towels, tote bags and lot more visit: https://custommadetshirts.co.uk/