Water based Inks and Plastisols: The Difference

Water based Inks and Plastisols: The Difference

When it comes to screen printing, water-based inks and plastisol are two popular out of multiple types of inks used in the textile printing industry. Both have their pros and cons and their differences with respect to their features, result and the fabric which they are suitable to.

Let’s delve into a detailed analysis of water-based inks and plastisols, comparing their characteristics, applications, and considerations:

Water-Based Inks

Composition: Water-based inks are primarily made up of water, pigments, binders, and additives. They are environmentally friendly and have low VOC (volatile organic compound) content. These inks dye the fabric of the shirt and replace its color instead of sitting on top of the shirt.

Characteristics:

- Soft and breathable: Water-based inks tend to create a softer and more breathable print, as they soak into the fabric fibers.

- Vibrance of colors: They offer excellent color saturation on a 100% cotton t shirt, while on a cotton/polyester blend or tri blend they give off somewhat a faded or vintage look.

- Good for light-colored fabrics: Water-based inks work best on light-colored fabrics, as they may not provide sufficient opacity on dark textiles.

- Reduced hand feel: Prints made with water-based inks often have a softer hand feel compared to plastisols, as the ink becomes part of the fabric.

- Longevity: These inks do not peel or crack over time and stay with the fabric forever.

Application:

- Suitable for natural fibers: Water-based inks are well-suited for printing on natural fibers like cotton, linen, and rayon.

- Preferred for eco-conscious brands: Due to their eco-friendly composition, water-based inks are often favored by brands seeking sustainable and environmentally friendly printing options.

Plastisol Inks

Composition: Plastisol inks are made from a PVC (polyvinyl chloride) resin combined with plasticizers, pigments, and additives. These inks cover the top of the t shirt with a layer of ink and does not soak in. They are a type of suspension ink and require heat curing for proper adhesion to the fabric.

Characteristics:

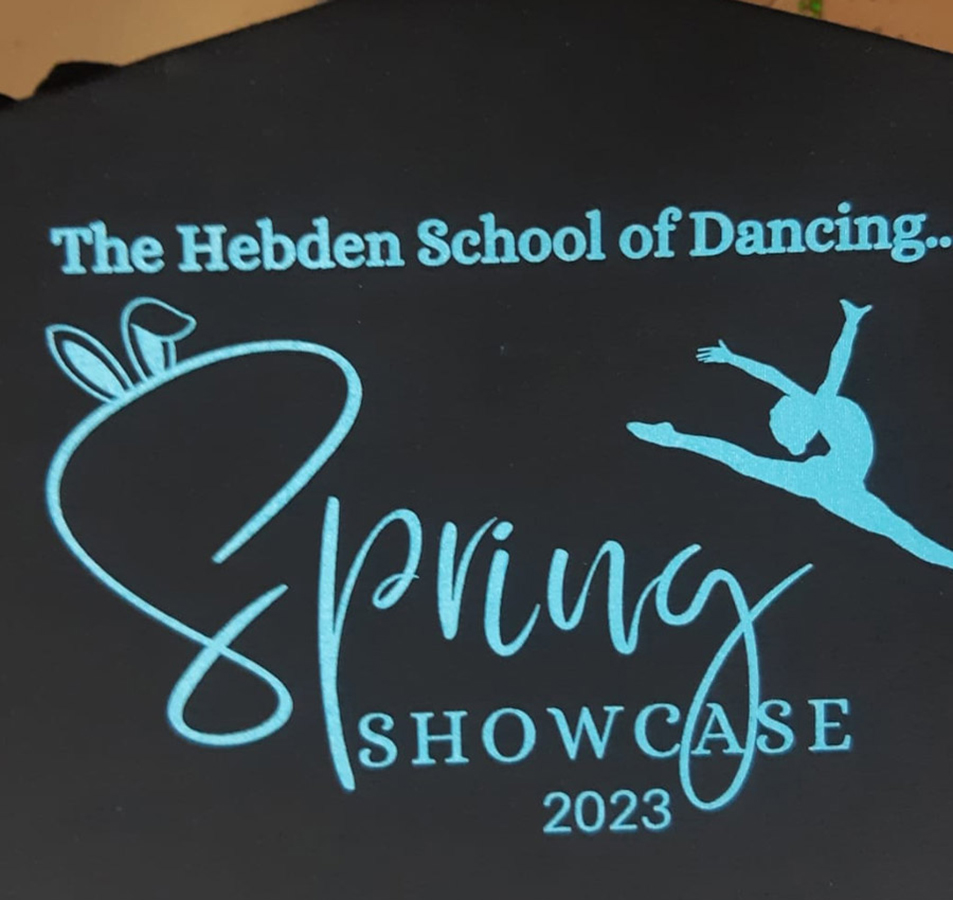

- Opacity and durability: Plastisols offer excellent opacity, making them suitable for printing on both light and dark fabrics. They also provide superior durability and colorfastness.

- Easy to work with: Plastisol inks have a thicker consistency, which makes them easier to handle and print, especially for detailed designs.

- High coverage: They have good coverage and can create sharp and opaque prints, even on textured or synthetic fabrics.

- Heavier hand feel: Plastisol prints tend to have a heavier hand feel, as the ink sits on top of the fabric rather than absorbing into it.

- Longevity: They eventually crack or peel off and tend to break down after some washes

Application

- Versatile for different fabrics Plastisol inks are suitable for a wide range of fabrics, including cotton, polyester, blends, and synthetic materials

- Popular in commercial printing: Plastisol inks are commonly used in commercial printing due to their ease of use, opacity, and durability.

Considerations

- Environmental impact: Water-based inks are generally considered more environmentally friendly, as they are non-toxic and have lower VOC content compared to plastisols.

- Print application: Water-based inks may require specialized equipment and processes, such as pre-treatment or heat curing, depending on the fabric and desired effect. Plastisols, on the other hand, can be applied directly and easily using standard screen-printing techniques.

- Cost effectiveness: Water based inks are tend to be more expensive as compared to plastisols which are long been used for screen printing.

- Design and desired effect: Consider the desired characteristics of the print, such as opacity, color vibrancy, breathability, or texture, to determine whether water-based inks or plastisols would be more suitable for a particular project.

In summary, water-based inks offer eco-friendliness, vibrant colors, and a softer hand feel, primarily suited for natural fibers and environmentally conscious brands. Plastisol inks, on the other hand, provide excellent coverage, durability, and versatility for various fabric types, making them popular in commercial printing. Ultimately, the choice between water-based inks and plastisols depends on specific printing requirements, fabric type, and desired effects.